Key Takeaways

- Wago 221 connectors improve ease and speed of electrical connections.

- Inline connectors offer a space-saving solution for tight installations.

- Suitable for dry environments, providing flexibility and reusability.

Overview of Wago 221 Electrical Connectors

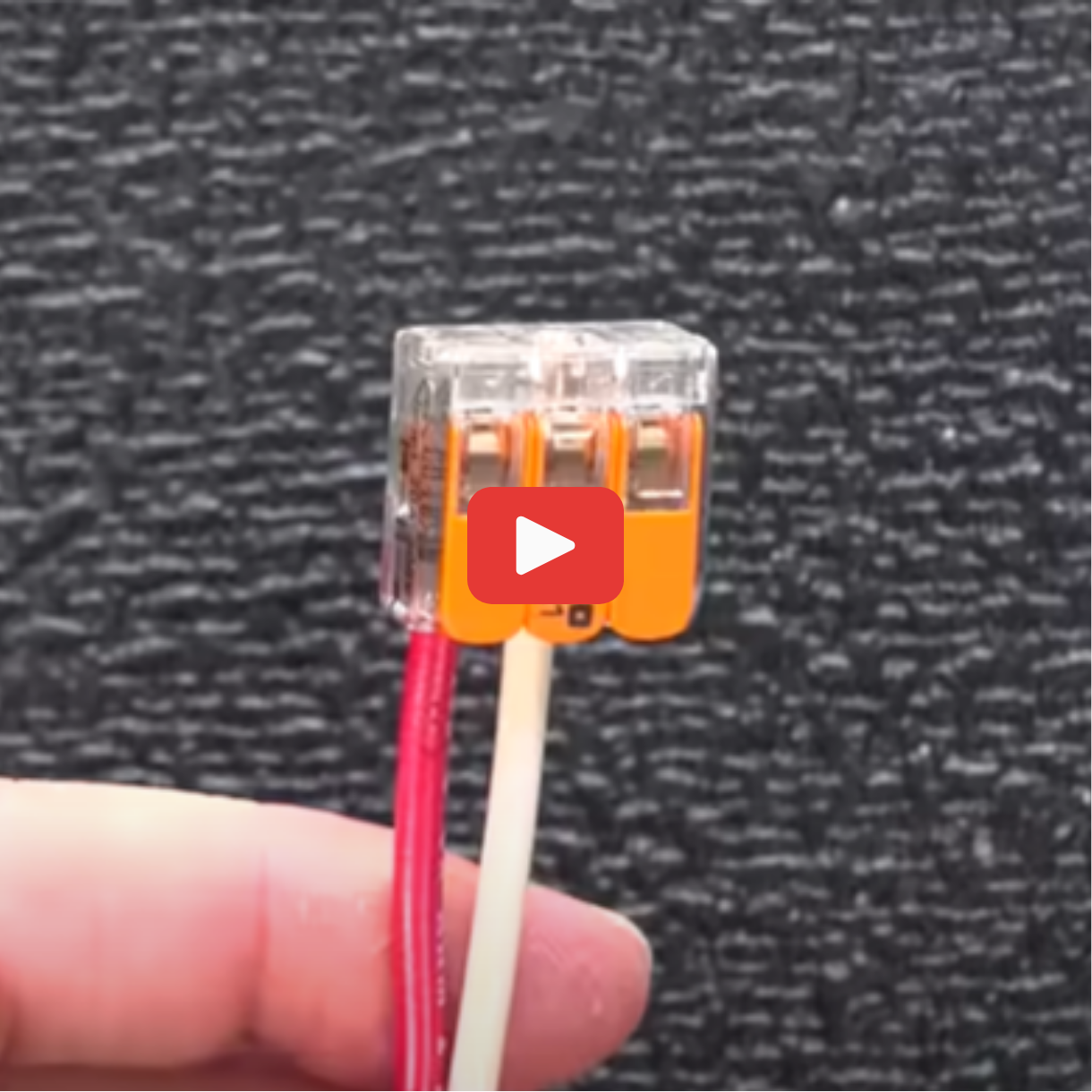

If you're looking to upgrade your electrical connection game, consider using Wago 221 electrical connectors. These connectors allow for quick and effortless wire connections by simply cutting and stripping your desired wire length, flipping up the lever, inserting the wire, and closing the lever. It's a straightforward process that ensures a secure connection every time.

One of the standout features of the Wago 221 connectors is their ability to handle various wire types and sizes. You can combine different gauge wires like 12 and 14, in a single Wago socket. The connector automatically adjusts the tension to hold each wire securely in place. Additionally, you can mix stranded and solid wire without any concerns, removing the worry of poor connections that can happen with traditional wire nuts.

The introduction of the inline connector variant expands the uses for Wago 221 connectors. Unlike the regular connectors, the inline version supports direct in-line connections, which is invaluable for specific applications like RVs, boats, or machinery. This setup provides a clean look and reduces the wire length needed.

While the inline connectors offer unique benefits, they aren't always the best solution for house wiring inside small junction boxes. Here, the standard Wago 221 connectors excel, due to their compact design which makes them easier to fold and tuck into tight spaces.

For those working in environments where the connectors might face snagging hazards, you can add electric tape or shrink wrap over the connectors for extra protection. Remember that while these methods add some barrier against dust, they are not waterproof solutions. Wago connectors excel in dry setups but can be used in wet-rated junction boxes with appropriate sealing.

Benefits of Lever Connectors Over Wire Nuts

Lever connectors, like the Wago 221, transform electrical connections, making them faster and more efficient compared to traditional wire nuts. Where wire nuts often create a guessing game, particularly when mixing stranded and solid wires, lever connectors eliminate this uncertainty. You simply cut, strip, and insert the wire with the lever flipped up, then close it to establish a secure connection.

With lever connectors, you can mix different wire types and sizes, such as 12 or 14-gauge, without concern for proper tension—it self-adjusts for a perfect grip. This capability is crucial when the risk of a failed connection is not an option. For those who have dealt with wire nuts, the possibility of them coming undone at critical moments is a familiar headache.

Features at a Glance:

- Compatibility: Supports mixing stranded and solid wires seamlessly.

- Efficiency: Reduces wiring length, offering a cleaner look.

- Adaptability: Suitable for in-line connections, perfect for RVs, boats, and machinery.

- Convenience: Allows easy disassembly; just lift the lever to adjust or rewire.

For jobs requiring parallel wire alignment, in-line connectors in the 221 lineup are ideal. They prevent unnecessary wire protrusion and save space. Environments such as inside junction boxes benefit from the traditional models, which fold neatly and offer flexibility when repositioning is necessary.

While the connectors enhance your work's accuracy and flexibility, remember they’re best used in dry wiring situations. They offer some protection against dust and dirt when wrapped with electrical tape or shrink wrap, but they aren’t intended for direct exposure to water or salt. Lever connectors are a game-changer for practical, efficient, and reliable electrical connections.

Mixing Different Types and Sizes of Wires

With Wago 221 connectors, you can effortlessly mix different types and sizes of wires. Whether you're working with 12-gauge or 14-gauge wire, these connectors handle each one perfectly. Just insert the wire into the connector socket, flip the lever down, and you're done. The connector adjusts to deliver the right amount of tension, ensuring everything stays securely in place.

A standout feature of the Wago 221 is its ability to effectively mix stranded and solid wires. If you've struggled with wire nuts in this situation, you'll appreciate how straightforward and reliable Wago connectors are. Each connection is secure and stable without the stress of wondering if it will come apart at the worst moment.

Key Benefits

- Quick and Easy Installation: No twisting or taping, just insert and clamp.

- Compatible Wire Types: Mix and match solid and stranded wires without issues.

- Secure Connections: Ensures a tight grip, perfect for electrical jobs where reliability is crucial.

- Compact Design: Ideal for tight spaces, providing a neat finish without extra wire extending out.

These connectors revolutionize how you handle mixed wire types, offering a modern solution to an age-old challenge in electrical work. Enjoy the peace of mind that comes from knowing your connections are solid and dependable.

The Newly Introduced Inline Connector

Introducing the new inline connector to the Wago 221 lineup brings a significant enhancement. It's designed to connect directly in line with your wiring, maintaining all the advantages of the standard 221 connectors. This development is crucial in various applications, such as RVs, boats, and tight home electrical spaces where wires run parallel and upright positions are impractical.

Consider a scenario where you need to replace a doorbell transformer inside your electric panel. The inline connector allows you to make a seamless connection, aligning wires perfectly in line and reducing excess wire length by about six inches. This not only gives a cleaner aesthetic but also makes room for potential future wiring expansions.

In constrained environments like RVs, boats, or machinery, space-saving becomes essential. Opting for inline connectors reduces the space needed for wiring. Also, they allow additional protections like electric tape or shrink-wrapping, offering security against tampering and some dust resistance. Although they’re not fully waterproof, pairing them with gasket-sealed junction boxes ensures safe use in wet-rated environments. Always remember to use them in dry wiring applications to maintain safety and performance.

Applications and Advantages of Inline Connectors

When working with electrical wiring, inline connectors can greatly simplify your tasks by reducing the need for extra wire length. They allow for direct, in-line connections without any parts sticking up, making them particularly advantageous in tight spaces such as electric panels. By minimizing the length of wire required, you not only achieve a cleaner and more organized look but also free up space for future wiring endeavors.

Inline connectors are invaluable in applications involving RVs, boats, and various machinery due to their compact size, which saves critical space. They support a mix of stranded and solid wires seamlessly within a single connection, removing the unpredictability often encountered with wire nuts.

Benefits of Inline Connectors:

- Space Efficiency: Reduces clutter in confined spaces.

- Ease of Use: Simplifies the process of making connections.

- Versatility: Suitable for a range of wire types and sizes.

- Durability: Allows the addition of electrical tape or shrink wrap for enhanced protection.

While inline connectors offer significant advantages, it's essential to select the right type for your specific applications. Traditional connectors may still be preferable for use inside junction boxes where space allows for folding and different wiring layouts.

Inline vs Traditional Connectors for Different Settings

When dealing with electrical connections, the choice between inline and traditional connectors can significantly impact both effectiveness and practicality in various settings.

Inline Connectors: These are particularly useful in scenarios where space is limited or wiring needs to be minimized. For instance, in settings like RVs, boats, or machinery, inline connectors reduce the space needed by keeping wires aligned, thereby offering a tidy and efficient solution. The compact design also enhances the aesthetic by minimizing visible clutter and providing extra room for future additions.

Traditional Connectors: In contrast, traditional connectors, such as Wago 221s, shine inside junction boxes. They allow flexibility and ease of installation, especially with pre-wired devices like motion-sensing switches. The ability to easily fold and hide connections within the box eliminates obstructions and ensures a clean installation. The reusability of traditional connectors stands out—they offer a simple way to change or correct installations by merely lifting the lever to release the wire.

Environmental Considerations: Remember that these connectors are ideally suited for dry environments. While inline models can be protected using electrical tape or shrink wrap, they aren’t entirely waterproof. For outdoor or moist settings, consider using them inside junction boxes with protective seals.

Deciding between inline and traditional hinges on your specific needs, with each option providing unique benefits tailor-suited to diverse scenarios.

Installation Demonstration With Motion Sensing Switch

Today, we're upgrading an old switch to a motion sensing switch. This is an excellent example of how to use Wago 221 electrical connectors to make wiring faster and more reliable. The motion sensing switch already has wires attached, making the process straightforward. Simply attach a Wago 221 connector to each wire.

Steps:

- Turn off the power to the circuit at the breaker panel for safety.

- Remove the old switch from the wall, carefully disconnecting the wires.

- Attach the Wago 221 connector to the wires on the new motion sensing switch.

- Insert the building wires into the Wago connectors. Ensure the levers are closed securely to finish the connection.

- Place the motion sensing switch into the wall box.

Using Wago 221s allows you to quickly connect wires without complications. If an error occurs, the levers make it easy to correct by releasing and re-securing wires. This approach also enables tidy wire management in the small space of a junction box, crucial for a neat installation.

With Wago connectors, wire handling is efficient and adaptable, providing freedom for future modifications. Reducing the length of wires leaves valuable space for any additional connections that may be needed later. The streamlined process enhances both the function and appearance of your electrical work.

Ease of Use and Reusability

Using the Wago 221 electrical connectors simplifies and speeds up electrical connections. You only need to cut, strip, and insert the wire, flip the lever, and the connection is secure. The innovative design accommodates various wire types and sizes, such as mixing stranded and solid wires, which traditional wire nuts struggle with. Lever-operated mechanisms ensure consistent and reliable connections every time.

A new addition to the Wago lineup, the inline connectors, allow for direct inline connections. This feature offers flexibility in environments like RVs, boats, and other tight spaces, reducing unnecessary wire length and providing a neat finish. Giving the ability to place wires parallel in such restricted areas enhances the usability, especially where space is premium.

For indoor tasks, the traditional Wago 221 connectors prove more effective. They fit effortlessly into compact spaces like junction boxes, providing convenient wire management. Should you need to adjust connections in the future, they allow you to easily lift the lever and remove the wire.

Additional features include the option to secure the inline connectors with electrical tape or shrink wrap. Although not waterproof, this provides some protection against dust and dirt. While suitable for dry environments, they can be used in weatherproof junction boxes for extra safety.

Resistance and Critics of Wago Connectors

While many have embraced the convenience and efficiency of Wago connectors, not everyone has been so quick to adopt them. Two distinct groups emerge when discussing these connectors: those who have tried them and are ardent supporters, and those who are steadfastly loyal to traditional methods, swearing by wire nuts.

Some argue that Wago connectors won’t surpass wire nuts in reliability or function. Despite the ease and speed of use with Wago connectors, skeptics remain firm, possibly due to long-standing habits or concerns about performance under various conditions.

A particular point of criticism is the potential exposure to elements like water, where Wago connectors may not hold up as reliably as alternatives due to their only partial waterproof capabilities. They are designed for dry environments, and although they can be safely enclosed within gasket-sealed junction boxes, caution is advised against using them in environments prone to moisture exposure, such as direct trailers or areas subject to water spray.

These concerns highlight the importance of considering specific use cases when choosing connectors, balancing ease and speed with environmental suitability and practicality.

Securing Connections with Electrical Tape or Shrink Wrap

When working with Wago 221 inline connectors, one effective method to secure your connections further is by using electrical tape or shrink wrap. These materials help reinforce the connectors, ensuring the levers remain in place and are less prone to being snagged or tampered with.

-

Electrical Tape: Applying electrical tape is a practical choice. Simply wrap it around the connector after making the connection. This adds a layer of protection against dust and dirt. However, remember that it doesn't make the connection waterproof.

-

Shrink Wrap: For a more durable option, consider shrink wrapping. Slide a piece of shrink wrap over your connection before securing the wires. Once connected, heat the wrap to shrink it around the connector. This provides a tighter fit than tape and contributes to a cleaner appearance.

While these methods enhance protection, they're not substitutes for the right environment. Always ensure your connections are in dry areas unless they're within a wet-duty-rated junction box. Avoid using them in places susceptible to water exposure, such as trailer wiring.

Suitability for Dry Environment Installations

Wago 221 connectors are excellent for electrical connections in dry environments. These connectors simplify the wiring process with their intuitive lever mechanism, allowing you to connect wires without the hassle of twisting wire nuts. You simply need to strip the wire, insert it into the connector, and flip the lever down for a secure connection.

Advantages:

- Mixed Wire Types: They support a mix of stranded and solid wires effortlessly, providing a reliable connection every time.

- Space Efficiency: These connectors, especially the inline version, are perfect for applications like RVs, boats, and machinery, where space is at a premium. They can help reduce wire lengths significantly, giving a cleaner and more efficient installation.

- Easy Adjustments: If you need to make changes, you can easily remove or adjust wires by lifting the lever, offering flexibility.

While these connectors provide many benefits in dry settings, it's important to note they are not waterproof. You should avoid using them in areas where they might be exposed to water spray or salt. However, they can be secured within junction boxes rated for wet environments, thanks to the gasket sealing.

Enhance your dry environment electrical installations with Wago 221 connectors for a hassle-free and efficient wiring experience.