Key Takeaways

- Outdoor lighting issues often start with bulb checks, especially incandescent ones.

- Wiring problems require isolating sections and continuity testing.

- Efficient troubleshooting balances simplicity and thoroughness.

Initial Service Call Description

Problem Overview

During the initial inquiry, the customer reported issues with several outdoor lights experiencing shorts and tripping the breaker. These lights are mounted on pedestal columns and controlled by a time clock. When manually engaged, the lights only illuminate briefly before the issue reoccurs. This suggests a possible fault within the circuit or components, such as the bulbs or wiring.

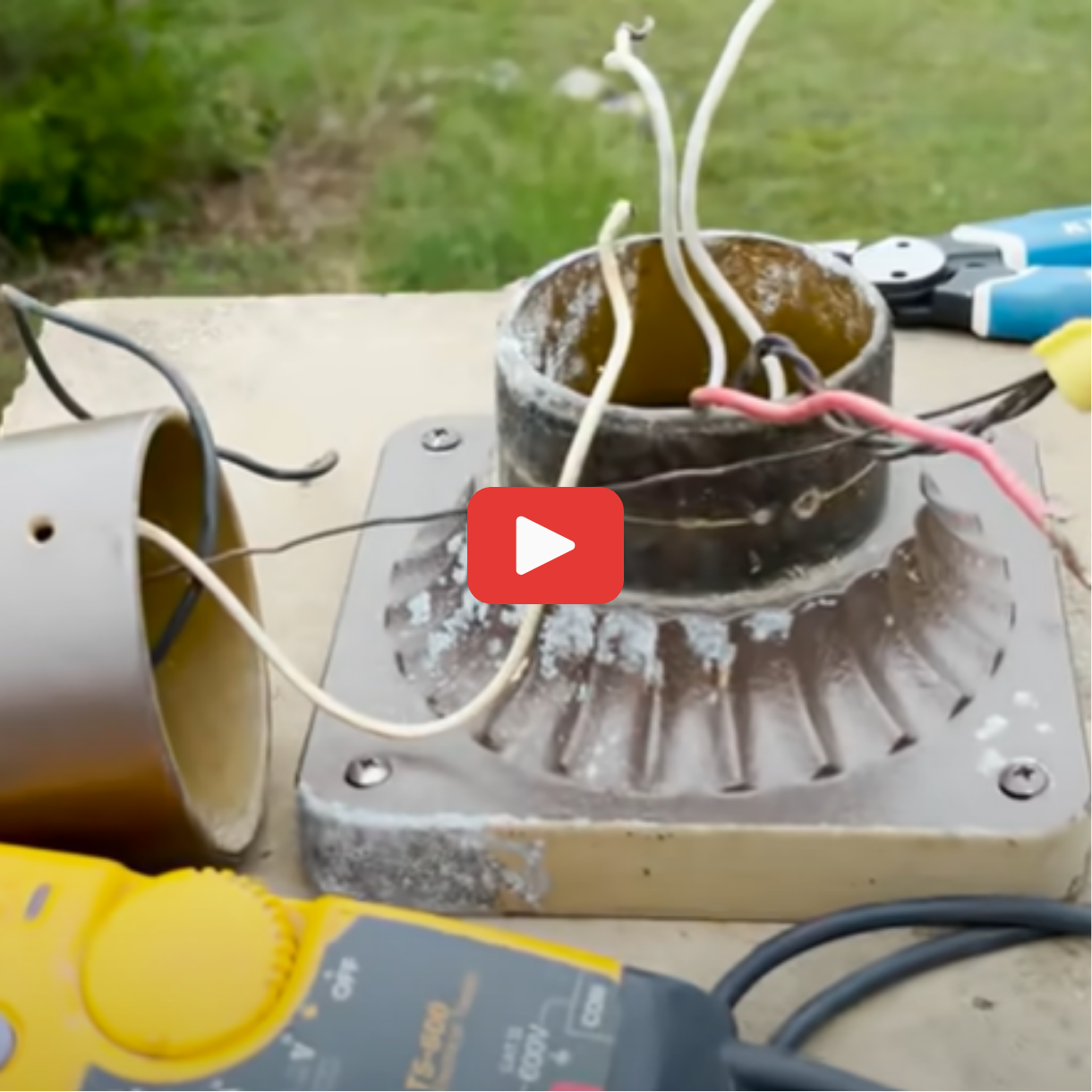

The troubleshooting process began with checking each bulb and fixture individually. Although suspected to be the culprit, the bulbs and fixtures were cleared of issues. The investigation then shifted focus to the wiring and connections, inspecting the integrity and continuity of the circuit. Various potential causes, including broken incandescent bulbs and improper use of non-weatherproof materials like Romex in outdoor conditions, were considered.

Time Clock Issue

The time clock, central to controlling the lights, presented consistent operational problems. Each activation caused the lights to trip the breaker, indicating a consistent malfunction. After evaluating the bulbs and fixtures with no resolution, attention was turned to the connections and wiring for potential faults.

Using a systematic approach, the wiring was isolated at different points to identify the source of the short circuit. It became evident that the issue was between specific fixtures due to faulty connections and possible circuit mismanagement. Ensuring correct wiring paths and verifying that outdoor circuits are protected against moisture and wear were deemed crucial steps to mitigate such failures in the future.

Diagnosing the Issue

Bulb Checks

Start by examining each bulb to ensure none of them are the source of the problem. Look for bulbs where the springs are still suspended properly. If any bulbs are broken or they have incandescent types with filaments, consider replacing them with LEDs for improved efficiency and durability. Incandescent bulbs can break and cause short circuits due to filament issues, especially in outdoor environments.

Further Fixture Examination

If bulbs are not the issue, inspect the fixtures and wiring. Check the continuity between each fixture’s wires and ensure there are no shorts between the black, white, or ground wires. Disconnect the joints to identify which half of the circuit might be faulty. Inspect each fixture individually, making sure both the fixture and its connections are secure and free of moisture or debris that could cause a short circuit. If issues persist, consider potential wiring errors between fixtures and note any discrepancies in expected wiring paths.

Reasons Against Incandescent Bulbs

Efficiency and Durability

Incandescent bulbs are notably inefficient, converting a large portion of energy into heat rather than visible light. This inefficiency can lead to frequent burnouts, particularly in unstable environments. They have fragile filaments that can easily break due to vibration or temperature changes.

Maintenance Inconvenience

The fragility of incandescent bulbs results in a need for frequent replacements, which is particularly cumbersome in hard-to-reach areas. For instance, when bulbs are installed in high ceilings, they often require special equipment like ladders or scaffolding for replacement, increasing both time and effort.

LED Advantages

Switching to LED lighting provides significant benefits over incandescent bulbs. LEDs offer enhanced energy efficiency, reducing electrical consumption and costs. They also come in various color temperatures, allowing you to customize the lighting ambiance effortlessly. Unlike incandescent bulbs, LEDs do not have filaments that can break easily, making them a more reliable and durable choice.

Electrical Troubleshooting Process

Simplifying the Approach

When tackling electrical issues, start with the simplest solutions. Begin by inspecting each bulb. Look for any that show signs of damage, such as broken filaments touching other parts of the bulb. Incandescent bulbs are prone to breaking, especially outdoors. Consider using LED bulbs instead for better efficiency and durability.

Circuit Division Strategy

If the issue persists, divide the circuit to narrow down the problem area. Disconnect joints at a central point to test the circuit's segments. If the breaker doesn’t trip, you know the fault is in the other half. It's a logical way to isolate and identify problems without unnecessary work.

Fixture by Fixture Inspection

When circuits involve multiple fixtures, inspect each one individually. Disconnect the fixture, check for internal shorts, and reconnect after inspection. This method allows you to systematically verify each fixture's condition and wiring.

Analyzing Wire Continuity

Utilize an ohmmeter for wire continuity checks. Measure between conductors such as black and white, black and ground. This helps identify if and where the current is unintentionally flowing. A clean continuity test from the line side confirms no short up to that point, allowing you to progress systematically.

Identifying the Wiring Issue

Isolating the Problem Area

When faced with a circuit shorting issue, start by assessing the simplest elements first. Begin by examining each light bulb for visible damage. Check bulbs individually to ensure filaments are intact, especially if they are incandescent, as these are more prone to breaking. Look for any signs of bulbs shorting the circuit.

Once bulbs are ruled out, consider the wiring. Trace the circuit path and identify a mid-point, then disconnect it to test each half separately. If the breaker still trips, move to physically isolating each fixture. Disconnect wiring at each point to narrow down the problematic area, being sure to check continuity between wires for signs of a short.

Discovery of a Compromised Wire

After isolating the system's various components, examine the wires closely for damage. In this instance, the culprit was a compromised red wire. Inspect the length of the wire to identify any scoring or exposure of the copper, which could make contact with a ground wire and cause the circuit to trip.

It is important to note the wiring environment. The use of Romex in outdoor or wet conditions is discouraged due to its susceptibility to moisture, which may degrade insulation over time. Opt for wiring methods suitable for the installation environment to prevent similar issues.

Electrical Code Discussion

Romex Usage in Wet Environments

Using Romex in wet environments is not recommended due to moisture-related issues. The material's sheathing can weaken over time due to the accumulation of moisture. Water exposure can lead to the insulation failing, which may cause shorts such as in outdoor applications. To maintain safety and functionality, it's crucial to avoid installing Romex in areas where it may be exposed to excessive moisture.