Key Takeaways

- Ideal push-in connectors are suitable for a variety of wire sizes and offer a clear view for confirming connections.

- Wago 221 connectors simplify wire installation with their lever mechanism and provide compatibility with both solid and stranded wires.

- While both connectors have advantages, considering their limitations in terms of electrical resistance and potential installation mishaps is essential for safe usage.

Ideal Push-In Connector Overview

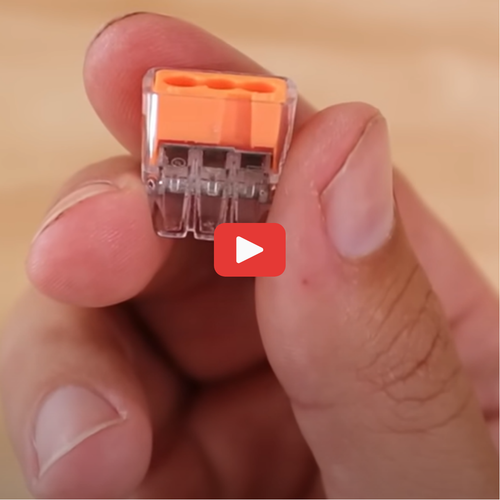

The Ideal push-in connector is equipped to handle a wide range of wire sizes, from #20 to #12 gauge. It operates by inserting the wire ends into holes at the bottom. The clear plastic allows for visual confirmation that the wires are fully seated.

- Wire Size Compatibility: #20 to #12 gauge

- Visual Confirmation: Clear casing to ensure full insertion

- Probe Testing: Channel and hole design for amperage testing while energized

The construction of the connector includes a metal piece that spans across the device, connecting all inserted wires and facilitating the supply of power from one to the others. It's worth noting that the metal piece is relatively thin, which can lead to higher resistance and potential heating.

- Material Considerations: Thin metal piece may increase resistance

In low amperage applications such as lighting, the Ideal push-in connector has proven to be reliable. However, caution is advised as there's hesitation among electricians to use these connectors in junction or receptacle boxes due to concerns about the aforementioned resistance and heating issues.

- Recommended Usage: Low amperage scenarios, like lighting

- Limitations: Not advised for junction or receptacle boxes due to higher resistance

Remember, the key with push-in connectors is to ensure wires are properly seated for secure and effective connections.

Pros of Ideal Push-In Connectors

-

Accommodates various wire sizes: Your Ideal Push-In Connector supports wire sizes ranging from #20 all the way up to #12. This flexibility is advantageous for working with different wire gauges in your projects.

-

Simple to use: The installation process is straightforward. Insert your wire into the bottom holes and push it until it's fully seated. This ease of use contributes to a smooth, hassle-free installation.

-

Visibility of connection: Thanks to the clear plastic housing, you can visually confirm the wire is properly seated. This feature helps ensure a secure and reliable electrical connection.

-

Testing access: A built-in testing channel allows for live circuit testing. Insert a probe into the hole to check amperage while the device is energized, adding a layer of safety and convenience to your work process.

-

Solid and stranded wire compatibility: Your Ideal connectors handle both solid and stranded wires, allowing for versatile applications and making it easy to connect different wire types.

Remember, while these connectors have their strengths, ensure they're used in appropriate scenarios—predominantly in low amperage situations such as lighting—where they perform well according to both personal experience and feedback from professionals in the field. As with any component, proper installation and usage are key to avoiding potential issues.

Cons and Usage Limitations of Ideal Push-In Connectors

The metal that connects wires within Ideal push-in connectors is quite thin, leading to reduced surface contact. This lack of ample contact area results in slightly higher electrical resistance. Consequently, these connectors might experience additional heating. When employing these in practical scenarios, it's advisable to restrict their use to low amperage applications. They have been effective in lighting projects where the demand on them is minimal.

Regarding installation in more critical areas such as junction boxes or receptacle boxes, there is a hesitance to recommend their use. This sentiment is based not only on personal reluctance but also echoes the concerns of other electricians. Elevated resistance and resulting heat could pose a risk in high amperage situations, which these connectors may not be ideally suited for.

|

Potential Issues |

Description |

|

Increased Resistance |

Thin metal leads to limited contact and higher resistance. |

|

Elevated Heat |

More resistance can produce more heat during operation. |

|

Specific Use Cases |

Best suited for low amperage applications, such as lighting. |

|

Professional Trust |

Some electricians hesitate to use them in junction or receptacle boxes. |

When you install Ideal push-in connectors, you should ensure they are employed within their effective range. For high-powered circuits and critical connections, considering alternatives with more substantial contact mechanisms might be prudent. Always prioritize safety and consult experienced professionals when in doubt about the appropriateness of these connectors for your electrical projects.

Wago 221 Connectors Explained

When handling your wire connections, consider the Wago 221 connectors as a reliable option. Its design accommodates a broad scope of wire sizes, from 24 gauge up to 12 gauge. This feature facilitates using the same connector for various applications within residential wiring, streamlining your inventory and processes.

These connectors employ an effective lever mechanism for securing the wires. To insert a wire, simply lift the lever to open the slot, place the stripped wire end into the input hole, then press the lever down to clamp the wire firmly in place. The exertion required to disconnect a properly secured wire is substantial, ensuring a stable connection.

Pros of using the Wago 221 connectors include:

- Clear visibility through the transparent casing to ensure full seating of wires.

- Compatibility with both solid and stranded wires.

- A stripping gauge on the side, indicating the precise amount of insulation to remove.

- Ease of modification by allowing for all wires to be released and re-secured quickly, should you need to add an outlet or perform servicing.

Despite these advantages, it's critical to note the potential for increased resistance and heat generation due to limited surface contact between the wires and the connecting bar within the unit. Experiences may vary—some professionals encounter overheating issues, while others report consistent performance without any problems.

A crucial tip when installing these connectors is to be cautious about the levers accidentally opening, especially when pushing the connectors into an electrical box. To avoid this, maintain pressure on the levers while positioning the unit. Once secured inside the box, release the levers to keep the connection intact.

In summary, Wago 221 connectors present a versatile, secure, and user-friendly solution for wire connections, with thoughtful features that enhance efficiency and reliability. Proper installation and mindful handling are key to maximizing the benefits of these connectors in your electrical projects.

Installation and Features of Wago 221 Connectors

When working with different wire sizes, Wago 221 connectors are capable of accommodating a wide range, from 24 gauge wire to 12 gauge wire. This versatility ensures that for residential wiring, a multitude of connectors are not necessary. The connectors can manage both solid core and stranded wires, ensuring strong connections between different wire types. The installation procedure is straightforward:

- Lift the levers on the top of the connector to open the insertion slots.

- Insert the stripped wire end into the slot and ensure it is fully seated.

- Press the lever back down to secure the wire in place.

The connector design incorporates a range of features to facilitate easy usage:

- Levers for wire insertion: These allow for the easy opening and closing of wire slots without requiring additional tools.

- Clear housing: Visibility is a key advantage, enabling you to confirm whether the wire is fully inserted.

- Strip gauge: Indicates the correct amount of insulation to remove from the wire, which helps in creating a secure connection.

Wire Compatibility Table:

|

Wire Type |

Gauge Range |

Acceptance |

|

Solid |

24 to 12 AWG |

Yes |

|

Stranded |

24 to 12 AWG |

Yes |

Despite the advantages, there are considerations to keep in mind:

- The connectors contain a metallic bar that, due to limited surface contact with the wires, might lead to higher resistance and heat generation. While this may not be an issue in low amperage applications, some electricians report overheating concerns.

- Careful installation is crucial to avoid levers opening unintentionally, which can occur if the connector snags on wires or the box during installation. To mitigate this, secure the levers when pushing the connector back into the box until it is properly positioned.

Lever Security Tip:

- While inserting the Wago connector into a junction box, keep your thumb on the levers to prevent accidental opening.

Advantages of Using Wago 221 Connectors

-

Versatility in Wire Sizes: You're able to use a wide range of wire sizes with the Wago 221 connectors. These connectors support wire sizes from 24 gauge all the way up to 12 gauge, which covers most requirements for residential wiring without the need for multiple connector types.

-

Transparent Design: The clear housing allows you to ensure wires are fully seated, providing confidence in your connections.

-

Ease of Use: Lever-actuated mechanism simplifies the insertion and securing of wires. To connect, simply lift the lever, insert the wire, and clamp it down by closing the lever. It's a straightforward process that offers strong, reliable connections.

-

Compatibility with Different Wire Types: The Wago 221 connectors can join both solid core and stranded wires seamlessly, giving you the flexibility to work with various types of wiring without hassle.

-

Convenient Testing Access: Integrated test slots make it easy to check the connections without disturbing the setup, ensuring that your system is functioning correctly while energized.

-

Safety Feature in Installation: When installing the connectors, keeping your thumb on the levers while pushing them into the junction box ensures they remain closed and prevents accidental disconnection.

-

Simplified Modifications: If modifications or repairs are needed, or if additional outlets are required, the connectors make it quick and easy to service. You just lift the levers, adjust the wiring as necessary, and secure it again.

-

Strip Gauge Guide: A strip gauge is provided on the connectors, allowing you to strip the perfect length of insulation from your wires for optimal connections.

|

Wire Type Compatibility |

Lever Mechanism |

Visual Inspection |

|

Solid and stranded wires |

Easy-to-use levers |

Clear housing for visual checks |

|

24 to 12 gauge range |

Secure clamping |

Integrated test slots |

Remember, when selecting a connector, it's important to consider these features to ensure a reliable and efficient wiring installation that meets your specific needs.

Potential Drawbacks of Wago 221 Connectors

-

Limited Contact Surface:

- The metal bar providing the connection has a limited surface contact area.

- This can lead to increased electrical resistance.

- Higher resistance often results in the connectors heating up more than desirable.

-

Compatibility and Usage Limitations:

- Despite their versatility in accommodating various wire sizes, from 24 to 12 gauge, their performance may vary with different applications.

- They are generally suitable for low amperage situations, such as lighting, based on personal usage and other electricians’ experiences.

- Trust issues have been raised regarding their use in junction boxes or receptacle boxes.

-

Risk of Inadvertent Disconnection:

- The connectors use lever mechanisms which, if snagged or incorrectly handled, can open unintentionally.

- This design flaw could lead to loose wires if the levers are accidentally flipped open during installation.

- A dislodged wire due to an open lever carries significant safety risks.

-

Installation Care:

- Ensuring a secure and proper installation is imperative.

- When inserting the connector into a box, care must be taken to prevent levers from opening.

- Recommendation: Keep pressure on the levers until the connector is securely in place to avoid accidental opening.

-

Inconsistency in Performance Feedback:

- Electricians' opinions vary, with some reporting overheating and issues, while others have not encountered problems.

- The disparity in field experiences suggests a degree of uncertainty regarding their reliability and safety in all scenarios.

Installation Tip: Confirm the leverage on the connectors is correctly engaged and be mindful when pushing them into boxes to prevent accidental opening of the levers.

Installation Tips for Wago 221 Connectors

For a successful installation of Wago 221 connectors, follow these practical steps:

- Begin by lifting the levers on the top, which opens up the entry holes for the wires.

- When inserting the wire, turn the connector over so you can clearly see the wire is fully seated at the top through the transparent housing.

- Once confirmed, press the lever down to secure the wire. It requires considerable force to pull the wire out once clamped.

- Check the strip gauge located on the connector for the precise amount of insulation to remove, ensuring a solid connection.

- The Wago 221 accepts a wide range of wire sizes, from 24 gauge up to 12 gauge, which is beneficial when working with various wire dimensions.

- You can use these connectors to join solid core wires to stranded wires effortlessly. Insert both the solid and stranded wires, verify their positions, and clamp them down.

Precautions to Keep in Mind:

- Ensure that you follow the correct installation procedure to prevent the connectors from overheating due to poor contact and higher resistance.

- When pushing the connector into an electrical box, secure the levers with your thumb to prevent accidental opening which can result in a loose connection.

- Be aware of feedback from electricians on heating issues, but also recognize that experiences vary significantly.

For reconfiguration or servicing:

- Simply lift the levers, remove the wires, and, if necessary, opt for a larger Wago connector to accommodate additional wires.

- Re-insert the wires into the new connector, making sure they are seated properly before clamping the levers down.

By following these steps, you can utilize Wago 221 connectors confidently, ensuring reliable electrical connections in your installations.