Key Takeaways

- MC cable is primarily used in commercial settings.

- Proper fittings are required for wet locations.

- MC must be correctly secured and supported.

Understanding MC Cable

MC, or Metal Clad Cable, is a common choice for wiring in commercial buildings and garages. Unlike many wiring options, MC cable includes conductors encased in a protective jacketing. This design makes it versatile for both indoor and outdoor use, though it is primarily rated for dry locations.

MC vs. AC Cable:

- MC Cable:

- Comes with either insulated or bare, full-sized equipment grounding conductors.

- Sometimes includes a second grounding conductor for bonding or isolated ground.

- AC Cable:

- Contains a thinner equipment grounding conductor.

- Typically not used interchangeably with MC.

When it comes to wet locations, you need to be cautious. Standard MC cable is not inherently moisture-proof. However, PVC-jacketed MC products are available for environments exposed to moisture.

Wet Location Installation:

- Ensure you use fittings rated for wet locations when terminating in these environments.

- If the termination point is in a dry location while the cable runs through wet areas, standard fittings suffice.

Permitted and Non-Permitted Uses:

- Allowed:

- Both exposed and concealed installations.

- Vertical runs with conductors of 250 kcmil or larger can be secured every 10 feet.

- Not Allowed:

- Areas subject to damage or corrosion unless specially coated MC variants are used.

Securing and Supporting:

- Secure MC cable within six feet or less for general applications.

- Specific rules apply for cables with four or fewer conductors sized number ten or smaller; these must be secured within 12 inches of a box or fitting.

- Support is generally required every six feet, except in certain cases like ceiling runs, where support can be every 18 inches.

For more structured installations or long exposed runs, conduit may be a better choice, even though the NEC allows the use of MC cable. Consider quality and aesthetics before making a decision.

Distinguishing MC from AC Cable

Understanding the differences between MC (Metal-Clad) and AC (Armored Cable) is crucial for proper usage in different environments.

MC Cable:

- Usage: Primarily in commercial buildings and garages. Not typically used in homes.

- Construction: Contains a full-sized equipment grounding conductor, which might be either insulated or bare. Some versions even have a second grounding conductor for specific purposes like bonding or isolated ground.

- Indoor/Outdoor Use: Suitable for dry locations. Some types have a PVC jacket making them suitable for wet locations.

- Conductor Types: Usually includes THHN or THWN conductors.

- Exposed/Concealed: Can be used in both, but may require additional strapping for neatness when exposed.

AC Cable:

- Usage: Can be used similarly to MC but is not as common in commercial settings.

- Construction: Contains conductors with a metal spiral-bound sheathing and a skinny internal equipment grounding conductor.

- Indoor/Outdoor Use: Primarily for indoor use without specific provisions for varying environments.

Key differences are highlighted in the table below:

|

Feature |

MC Cable |

AC Cable |

|

Primary Use |

Commercial buildings, garages |

General-use, less frequent in commercial |

|

Equipment Grounding Conductor |

Full-sized (insulated or bare) |

Skinny internal wire |

|

Outdoor Use |

Yes, with appropriate PVC jacket |

No specific provisions |

|

Conductor Types |

THHN, THWN |

Varies, typically general conductors |

|

Exposure |

Can be exposed with proper strapping |

Standard indoor, not exposed |

You must choose the correct cable type based on the environment and specific usage requirements to ensure safety and compliance.

Construction and Features of MC Cable

MC (Metal Clad) cable is a type of cable assembly where conductors are enclosed in a protective metal jacket. It is predominantly used in commercial buildings and garages, although it can be applied in residential settings as well.

Components of MC Cable

- Conductors: Typically, the conductors inside MC cable are THHN or THWN, providing protection for dry and wet locations.

- Equipment Grounding Conductor: MC cable includes a full-sized, insulated or bare equipment grounding conductor. Certain versions may include a second grounding conductor for bonding or isolated grounding purposes.

- Sheathing: The external metal sheath provides mechanical protection, but it is not rain-tight or moisture-proof.

Usage Conditions

- Indoor and Outdoor: MC cable can be used both indoors and outdoors in dry locations.

- Wet Locations: For use in wet environments, a PVC jacketed MC cable is available, which is impervious to moisture. This type requires appropriately rated fittings at terminations.

Installation Notes

- Securing and Supporting:

- MC cable must be secured and supported within 6 feet intervals.

- For vertical runs down walls with conductors 250 kcmil or larger, securing every 10 feet is permissible.

- Cables with four or fewer conductors of size 10 AWG or smaller must be secured within 12 inches of a box or fitting.

- Exposed Installation: It is permissible to install MC cable exposed on walls, though its aesthetic may not be appealing. It usually requires additional strapping to keep it aligned.

Environmental Considerations

- Corrosive Environments: MC cable should not be used in areas prone to corrosion unless a specially coated variant is employed.

- Damage-Prone Areas: Avoid using MC cable where it can be easily damaged by external forces.

Applications and Usage of MC

MC Use in Commercial Buildings and Garages

MC is commonly utilized within commercial buildings and garages. It's preferred due to its durability and reliable performance for electrical wiring. While it could potentially be used in homes, its primary applications are in commercial settings where its full-sized equipment grounding conductor provides enhanced safety.

Indoor and Outdoor Installation

MC can be installed both indoors and outdoors. For outdoor use, it's important to note that while the conductors are often rated for damp or wet locations, the sheathing itself is not inherently moisture-proof. Using a PVC-jacketed MC with appropriate fittings ensures compatibility with wet locations, providing the necessary insulation against moisture.

Comparison of Dry, Damp, and Wet Locations

Here's a comparison of how MC can be used across different environments:

|

Environment |

Description |

Requirements |

|

Dry |

Typical indoor settings |

Standard MC without special fittings can be used |

|

Damp |

Areas with occasional moisture |

Not specifically addressed in UL listings; careful consideration needed |

|

Wet |

Constant exposure to moisture |

PVC-jacketed MC with moisture-rated fittings required; must be marked clearly |

In dry locations, standard MC is sufficient. For damp locations, although not specifically listed for such use, caution is necessary. For wet environments, using PVC-jacketed MC and ensuring all terminations are with appropriate wet-location fittings is essential for compliance and safety.

Handling MC in Damp and Wet Environments

Wet Location MC Cable Features

MC cable can be used outdoors, but it's essential to understand that the jacketing is not automatically rated for wet environments. For wet locations, you need to ensure that the cable's conductors are protected. Typically, the conductors inside MC cable are THHN or THW, which offer some level of moisture protection. However, the sheath itself is not inherently moisture-proof.

Utilizing PVC Jacketed MC for Moisture Protection

To use MC cable in damp or wet environments, you can opt for PVC jacketed MC. This type of jacket is impervious to moisture, making it suitable for such conditions. PVC jacketed MC will typically be marked appropriately for direct burial and other specific uses in wet environments.

Fitting Requirements for Wet Locations

When terminating MC cable in a wet location, you need to use fittings rated for wet environments. Bridgeport, for example, provides fittings specifically for this purpose. If the termination point is in a dry location, you can use standard fittings. Properly rated fittings ensure that moisture does not infiltrate the cable ends or the connected equipment.

MC Cable in Exposed and Concealed Settings

When working with MC cable, you can use it in both exposed and concealed settings. If you need to run the cable down a wall, it's perfectly acceptable whether it's covered with sheetrock or not. Exposed MC cable doesn't always look as neat, and it might be a good idea to strap it more frequently than the minimum standard to keep it straight.

Important Points:

-

Exposed Settings:

- Can be used on walls, ceilings, and other visible places.

- Frequent strapping may be necessary to maintain neatness.

- Personal preference might lead you to use conduit instead for aesthetic reasons.

-

Concealed Settings:

- Often used behind walls or in areas out of plain view.

Make sure to follow the NEC code, which fully supports using MC cable in exposed places. When it comes to securing and supporting MC cable, here are some guidelines to keep in mind:

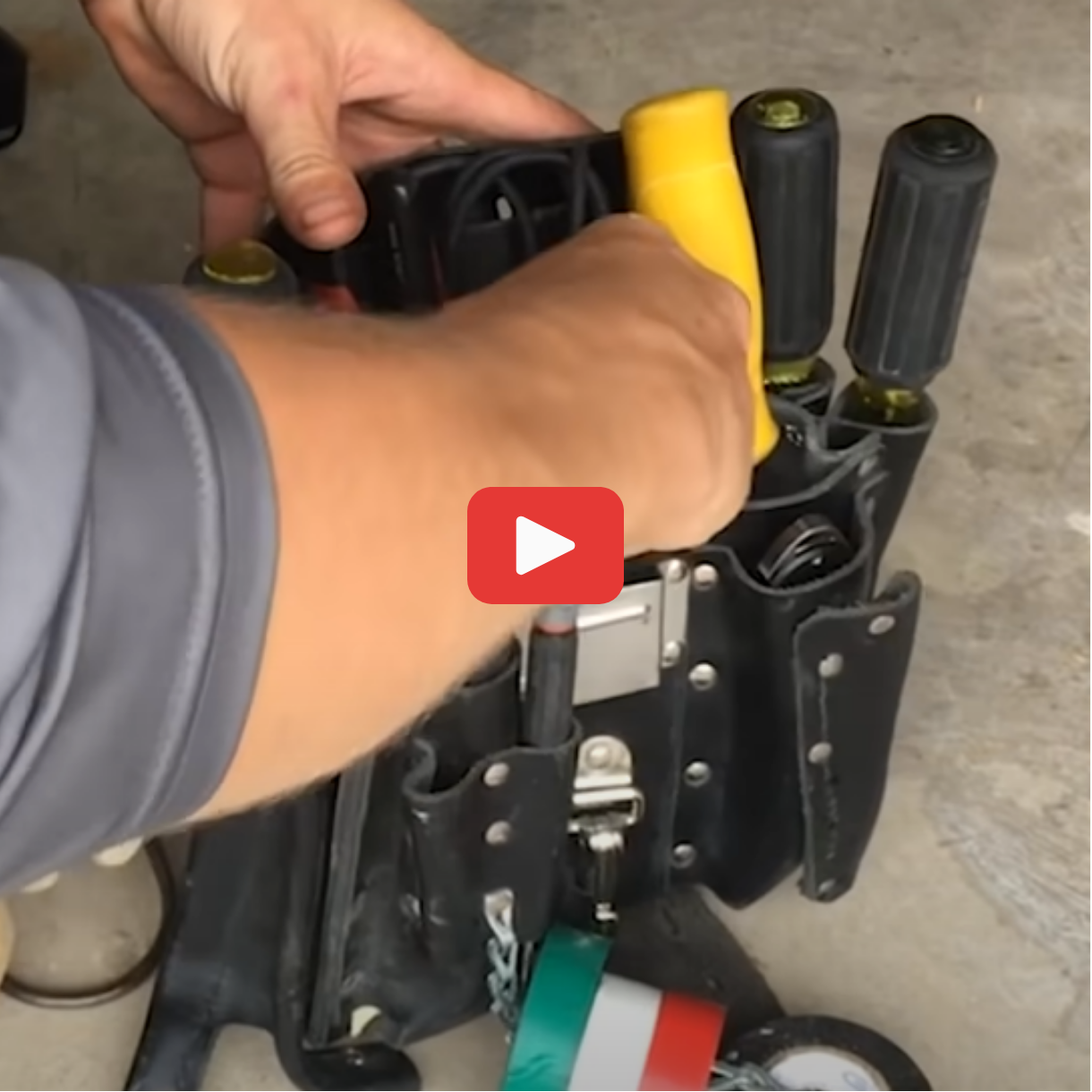

Securing:

- Attach cable within 12 inches of junction boxes, cabinets, or fittings.

- Straps, staples, or similar devices can be used for securing.

Supporting:

- MC cable should be supported every 6 feet.

- In specific scenarios, such as with larger conductors, you can support them every 10 feet.

Restrictions:

- Not suitable in areas where it could be easily damaged or exposed to corrosion without proper protection.

- For wet or damp locations, use a PVC-jacketed MC product and ensure you have the appropriate fittings to prevent moisture ingress.

By adhering to these guidelines, you can ensure proper installation and longevity of your MC cable, whether it's exposed or concealed.

Sponsor Segment: Rogers Electric

Today's episode is brought to you by Rogers Electric. I have gotten to know Rogers for quite a while now. I’ve had the opportunity to head out to the field, work with their team, and visit their corporate office. This experience has given me great insight into their operations and dedication to quality and education.

Rogers Electric specializes in commercial service work and also handles construction projects. Their commitment to excellence is evident in every aspect of their work.

For those of you who are curious about Rogers Electric and want to explore more, you can find a link in the description below.

Restrictions on MC Cable Use

Avoidance of Damage-Prone Areas

You should never use MC cable in areas where it is likely to get damaged. For example, environments where heavy equipment or frequent movement is expected. MC cable is relatively easy to break if bent or struck, so always ensure it is installed in locations where physical harm is minimized.

Corrosion Prevention Considerations

Corrosion is another critical concern when using MC cable. Avoid using MC cable in corrosive environments unless it has a specific protective coating or is otherwise rated for such conditions. This helps to ensure the longevity and reliability of the cable in harsh environments.

Securing and Supporting MC Cable

General Securing and Supporting Guidelines

Securing and supporting your MC cable is crucial for both safety and code compliance. The basic rule is to secure and support the cable within six feet intervals. Securing typically involves using straps or clamps to lock the cable in place. Supporting means ensuring the cable is held up, often running it across trusses or rafters.

Exception for Large Conductors

For vertical runs with large conductors (250 kcmil or larger), you can secure the cable every 10 feet instead of six. These massive conductors are rigid enough, almost like piping, thus don't require as frequent securing.

Strapping Requirements Near Boxes and Fittings

When working with MC cable that has four or fewer conductors sized 10 AWG or smaller, you need to secure it within 12 inches of a box, cabinet, or fitting. This rule doesn't apply to every type of MC cable, just to these specific configurations. Using adequate strapping near terminations ensures stability and safety, particularly in the case of smaller conductors.